October of last year Genie Garage Door Opener had me out to tour their facilities in Ohio. They also hooked me up with a garage door opener (even though I don’t actually own a garage). Fortunately, the OPC workshop is a converted garage, and that gave me the perfect opportunity to install the Genie PowerMax 1500. This article is an overview of the installation process.

A Quick Note: OPC just sponsored a giveaway over on Young House Love. Sorry, entries are closed, but I wanted to take a moment and welcome any new readers! If you’re new to OPC, learn more about us here including details about our Project Rewards program where you can get free stuff like this. If you’re more interested in crafts, decor and style, be sure to check out OPC’s Better Half.

Pro-Follow Update: Here at OPC, Pro-Follows are the “meat-and-potatoes” of our content, and I’m excited to get started on a bathroom remodel with Steve Wartman and his crew next week. Stay tuned for details!

How to Install the Genie PowerMax 1500

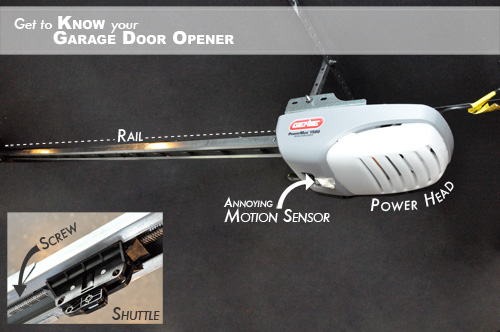

The PowerMax 1500 is a screw-drive garage door opener, and that’s good because there are no belts, chains or gears that wear out. Screw-drive openers are also very strong, and almost maintenance free (lubricating the drive-screw and double-checking the Safe-T-Beam system). The PowerMax 1500 has a direct current (DC) motor, and that enables variable speed control for things like the “soft close” feature.

The project started by taking down this Craftsman opener. Swapping in a new opener is much easier because if you’re lucky, you can reuse some of the mounting hardware and wiring. Plus, you don’t have to worry about running a power supply.

Before you purchase an opener, you need to measure the garage door and make sure that the rails can accommodate the door height. Most household garage doors are 7′ tall.

The segments of this rail system are joined together with these rail connectors. After installing this opener, I’d actually prefer bolting the rails together (like some of the other Genie models) because the connectors can create noise as the door opener is running.

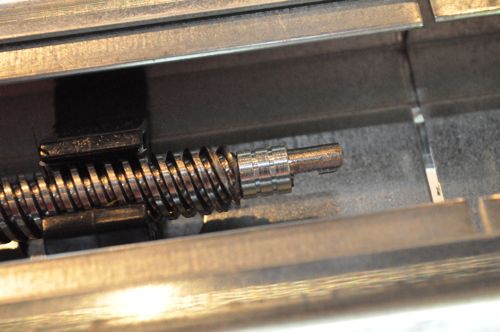

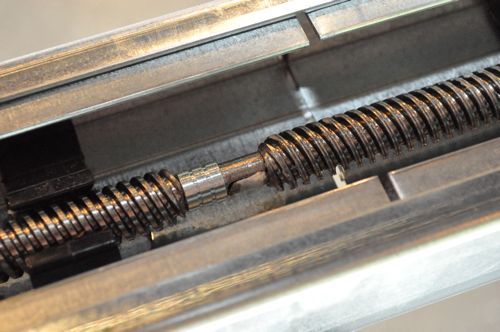

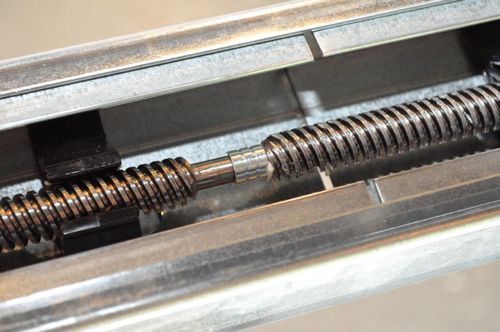

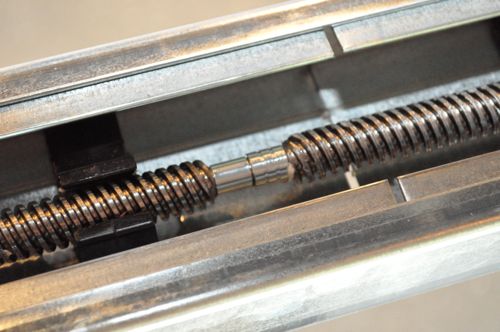

After joining the rails, you need to connect the segments of the screw, and Genie did a great job keeping this simple. All you have to do is slide a collar on, and then snap a spacer in place behind it.

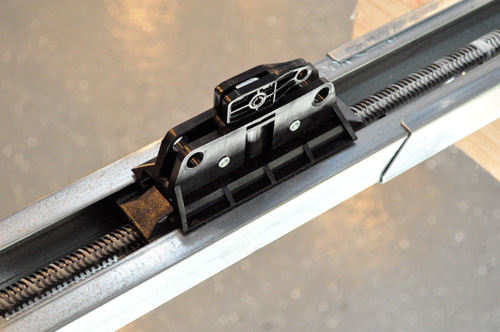

The shuttle (pictured) slides along the rails and attaches to the carriage (the part that actually moves along the screw).

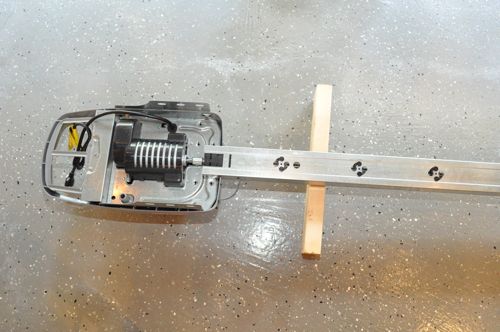

With the rails in place, the whole assembly attaches to the power head.

Mounting all this on the ceiling was kinda tricky because I was working alone. In the end, I used the garage door to support the rail, and I carefully attached the power head to the bracket.

Here’s a shot of the header bracket that holds the opposite end of the rails above the garage door.

And this is the door bracket which connects to the shuttle via the door arms.

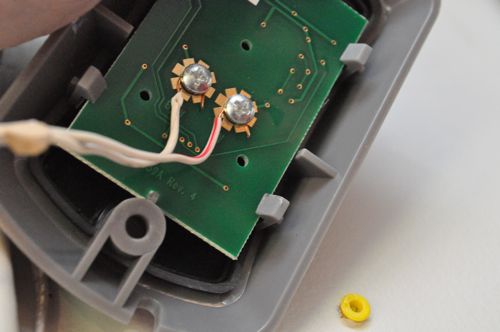

Positioning the Safe-T-Beams was really easy. I don’t know if I just got lucky or if it’s always this simple. I just mounted the beams to the wall framing, and that was it! There was no need to adjust their positions.

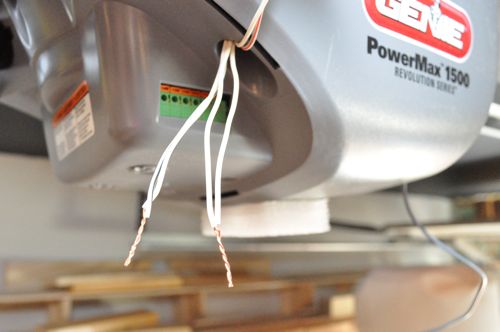

Like I mentioned, it’s great to reuse the old wiring. Each Safe-T-Beam has two wires, and the wall-mount button also has two wires. Everything slides into the convenient push-in connector.

One of the nice things about the wiring on the sensors and the wall mount is that the wires are interchangeable.

With everything wired up, all that’s left is installing a couple of light bulbs and the lens. If you look closely in this picture, you’ll notice that I taped over the motion sensor. Unfortunately, there’s no way to turn that off! Other than that, the opener works well.

How I typically mount an opener is to fasten the rail bracket to the header, then the rail to the bracket and let the motor rest on the ground. Then I put the motor up on top of a 6′ step ladder while getting the strapping in place. Then attach the motor to the strapping.

Looks like a nice opener.

So far, I’m pleased with it. I’m also glad it’s a 1 hp model so that if I ever get around to installing insulated garage doors, it’ll be able to handle the extra weight.

Hey, did you ever announce who won the garage door opener last fall? I didn’t see the announcement. We were waiting to see if we won since we had to install a new one. Finally had to go ahead and purchase one. 🙂

I don’t know that we announced it publicly, but we did send the opener out. We’ve actually got another on hand right now, which will likely end up in our Rewards Center.

Ooh, nice reward!

I do pretty much the same as Jeff does, install the header end first, then lay the unit on the ladder, it’s much easier that way for me.

Ethan, is there an improvement that makes this model maintenance free? I have never seen one that doesn’t require periodic lubing along the screw itself (usually with white grease), It’s not a difficult, or time consuming task, but still one that should be done a couple times a year on other models I have dealt with.

I’m not sure the answer to this one (ethan will likely weigh in too), but I can say that the screwdrive model we have on the other side of the garage has not been lubed in 3 years (since installation) and is still working great. But it does require annual lubrication, per the instructions, so I guess we should be getting on that. I like the screwdrive models for their strength and simplicity, but the maintenance requirement and noise are drawbacks. Belt drive systems are quieter, but some belts also require maintenance with constant use.

If noise is a problem, you will be glad to know that in my experience, lubing them does significantly quiet them down.

I agree with you on all points, the screw drives are impressively powerful lift platforms, but never as quiet as belt/chain drives.

You know, I was making that statement based off the product details. Looking through the owners guide, it mentions (like you did) lubing the screw. I’m not sure how they can claim it’s a “maintenance free drive screw.” Good comment, and I’ll update the post.

Ethan, it was just one of those things that occurred to me, from age, and experience, (and having had 3 of similar Genie units in my own home). I hope you understand there was no snarkiness implied:)

No snarkiness taken! I love it when readers add their own experiences (and keep me honest).

Did you install two as I see you have a two car garage

We already had a Genie screw drive on the other door, setup 3 years back! It’s still going strong.

awesome 🙂

Great review. Having no garage to deal with, I am out of my league with these things, but all the ones I think I have ever seen have been belt driven (or at least not screw driven). I’ll definitely bookmark this for when I have a garage, though.