Update: Several readers have noted that the membrane installation method described in this article (which is a flat membrane installation) is no longer recommended as an optimal installation method because water that penetrates through the top layer of tile or grout may rest on the membrane. Without what is known as a “pre-slope fill,” this water may never work its way to the drain. A pre-slope fill mortar bed installed under the membrane, coupled with the proper method for ensuring the mortar does not block off weep holes to the drain, can better protect the installation from standing water than may not evaporate back through the surface tile and grout. This updated method can be seen in this article at The Family Handyman. Note that the below method may still meet code in some areas, so if you are dealing with a professional installer, you may want to discuss their methodology. Next time we have a chance to follow a professional on a shower pan install, we will update this article to include the revised method.

——

Regular readers know that I’ve been hanging out with general contractor and carpenter Joe Bianco. In preparation for moving, Mr. and Mrs. Homeowner have tasked Joe with remodeling three full bathrooms, and he has brought in Jim and Rich from Diamond Tile to pour the shower pans and lay the tile. Jim and Rich have been laying tile for over 20 years, and I’m pleased to share how they poured the shower pans. Read on to learn how they waterproofed the shower, what materials they used, how they sloped the pan for proper drainage, and created a shower pan that’s ready for tile.

Prep

Before Jim and Rich got started, Joe and the plumber have made some important preparations. You can see a curb has been installed by stacking three 2×4’s and blocking has been added between the wall framing. Also, the subfloor has been brought up to the necessary level for the drain. The guys used concrete board because it was handy and the right thickness. However, the subfloor is usually plywood.

The plumber installed a polyurethane waterproof sheeting.

Instead of cutting the sheeting and compromising the waterproof barrier, the plumber overlapped the membrane in the corners (like hospital corners).

He used roofing nails to secure the sheeting because they have broad, flat heads. All the nails were placed at least 4″ up from the subfloor in accordance with local code.

Next, the guys installed Durock concrete board on the walls. Again, you can see the nails are at least 4″ up the wall.

After the sheeting was in place, the plumber finished with the drain flange and drain.

Here’s a look at the second bathroom after the Durock was hung and the drain completed.

Pro-Tip: Sometimes you’ll see the floor pre-sloped before the base is poured. Jim and Rich will do that when the floor is way out of level or when the drain is significantly higher than the subfloor. On these bathrooms it was not necessary.

Step 1: Clean

Before getting started, the Jim used a foxtail brush to clean away debris.

Step 2: Cover Drain

Next, Jim covered the drain with tape to prevent it from clogging.

Step 3: Mix Mud

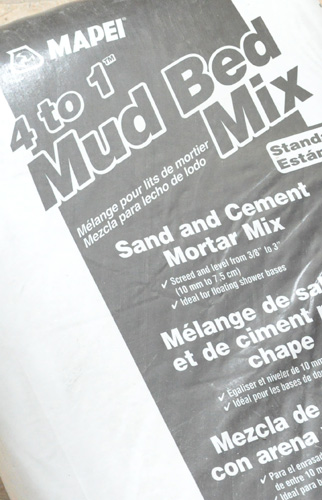

For the shower pan, the guys used Mapei 4 to 1 Mud Bed Mix. You won’t find this at your local DIY center. Instead you’ll have to go to a local tile supplier, and each bag costs about $15.

Pro-Tip: A cheaper alternative to Mud Mix is all-purpose sand and Portland cement. Jim and Rich prefer Mud Mix because it saves time.

Pro-Tip: The average sized shower base requires 3 – 4 bags of Mud Mix.

Using a mixing paddle to mix the mud, Jim added water until he achieved the right consistency, and he targeted a “dry mix” that is just wet enough to clump together when compressed. A dry mix enables the guys to work the mud and set the necessary slope without concern that it’ll move, and it will dry just as hard.

Step 4: Pour / Spread Mud

Jim poured three buckets of mud into the shower and spread it out with a straight trowel.

Pro-Tip: Jim and Rich don’t use a wire mesh reinforcement for the shower pan because it’s not necessary, and if you’re not careful when packing and spreading the mud, you can puncture the waterproof membrane.

Step 5: Pack Edges and Corners

Since the Durock isn’t nailed at the very bottom, it can shift a slightly. To eliminate any movement, Jim packed some mud tight against the perimeter and into the corners.

Step 6: Set Mud Around Drain

Next, Jim began setting the mud around the drain, and he used a floor tile to find the appropriate height. After the tile is installed, it should be flush with the top of the drain. That means the base should allow room for the tile height plus a little extra for thinset.

Pro-Tip: The mud around the drain should be at least 1″ thick to provide a strong base.

Step 7: Set Slope

Using a 2′ level and the drain as a reference point, Jim sets the slope for the shower pan, and it should be 1/4″ to 1/2″ per foot.

After Jim determined the right slope between this corner and the drain, this corner became the new point of reference for the remaining perimeter.

Step 8: Level Perimeter

Working out of that corner, Jim leveled the rest of the perimeter, packing the mud firm. Jim also looked for gaps under the level and filled them accordingly.

Step 9: Screed and Trowel

After the drain was set and the perimeter was at the necessary slope, Jim began filling the remaining area. He used the level as a screed and the trowel to finish the mud.

Step 10: Check for Low Spots

Jim went back and carefully looked for low spots with his level. He said you can usually feel them as you work the trowel across the mud.

Pro-Tip: Jim says that failing to maintain a consistent slope and fill low areas is the most common mistake when pouring a shower pan.

Step 11: Verify Slope and Drain Height

After Jim finished filling and screeding, he went back to verify the slope of the shower base and to double-check the height around the drain.

Pro-Tip: The drain flange is threaded and the drain height can be adjusted. Just be sure to preserve the necessary slope.

Finished

Jim and Rich did two pans in this fashion, and they look great. The guys will let this set overnight before starting to lay tile.

Pin for Later

Great work by Joe and his crew… a work of art. props to you too Ethan. thanks for sharing.

Thx JB. I always appreciate the comments (not to mention the social media sharing)!

Rubber cement used to secure those preformed pieces over the curb? Also is the seat sloped and did they use membrane there (maybe paintable membrane before tile)?

I gotta double check but it looks like some sort of adhesive for the curb corners (from the pic), and I know it’s secure. I’ll find out what they used. I’ll also verify the slope on the seat, but I’d be surprised if they missed that. They covered the seat with the same membrane too.

I have done a couple..next one I will make threshold and base, all of concrete, but in one continuous pour. Not the threshold, and then the base ,,, because I think will crack at the corner then??

What kind of time frame does the Mud Mix give someone to work with before it starts drying? And how long to completely set?

Looks good though! I’m surprised at how smooth it turned out after all that by hand

The Mud Mix gives you plenty of work time, and Jim and Rich let it set overnight before tiling.

This looks really great. You can tell this guy really takes pride in his work. Craftsmen are hard to find these days, but it sounds like you may have found a couple.

Maybe you’ll talk more about this when you post about laying the tile, but I’m curious about whether they tried to create flat planes around the drain, or if the whole thing is continuously curved. I’ve seen some showers where they try to make four grade breaks extending from the drain typically out to each of the four shower corners (maybe five in this case with the seat). The area between these grade breaks is a flat plane. I’d imagine if the whole thing is curved it would be more difficult to tile, although maybe the curve is so subtle that it won’t matter?

Hey Reuben,

It’s a straight shot (flat) between the perimeter and the drain at any point, and that makes sense because they used a level to screed it. The guys didn’t section the pan off into separate parts (or grade breaks as you put it). They just extended that same slope out from the drain in all directions. Does that make sense?

Amazing job and explanation. It looks flawless in that last picture thats the kinda guy you want working on your bathroom reno.

sooo. how does the membrane tie into the drain to get rid of any water that might have made it through?

Working from the pictures I’ve taken….. The drain assembly is composed of a couple different pieces. The first piece connects to the PVC drain and sits flush with the top of the concrete board. The next piece is attached with four bolts and the membrane is sandwiched in between the two. Lastly, the drain is screwed into the second piece and that sits flush with the tile.

The drain has weep holes built into it ,,that when installing the mud,,pebbles are normally put around these weep holes so that the mud does not close them off.These weep holes are there to carry any water into the drain when any water eventually seeps thru the mud base ..They say that is why the vinyl pan is installed in this type of ceramic tile construction. Acrylic shower bases can be installed but then the tile floor would not be available only the wall tile,,but they are a NO LEAK substitute..

The weep hole are a very important part of this application, there is such thing as a weep hole protector, a plastic ring covering these holes, also wire lathe can be used along the curb to tie in the mud floor to curb! Before the mud went in, 2 “ tape should have been applied to all seems and corners, then a waterproofing membrane painted on the cement backer board, since water will penetrate it! Wedi board is a much better choice! So much to the science of a shower/pan system!

beautiful work. Can’t wait to see how it turns out!

Almost makes me want to tackle this on anew house…ALMOST

I don’t to want be negative, but I see that they screwed the backerboard on top of the the curb. This might cause leaking into the membrane and into the wood structure, wouldn’t it?

One tutorial I saw, advised the curb to be cemented with a mesh screen and concrete troweled over it.

Nice job though.

Hi Jay,

Thanks for the comment. I’ll ask the guys next time I can about the potential problems. I will say they’ve been doing this a long time so I expect they’ll have a good justification for the way they did it.

I asked them about using wire mesh reinforcements, and they said it wasn’t necessary for the pan (didn’t comment on the curb), and that they can easily puncture the membrane so they avoid using them.

Hope to see you around OPC again.

How long does the cement in the drain pan take to cure before you can use the shower? (this is after the tile has been installed and grouted)

Thanks,

Christine

If I’m not mistaken, there is supposed to be a preslope under the membrane to direct any penetrating water to the weepholes under the tile bed. The liner installed here is relatively pointless as any of that water that seeps through the grout or at the corners will just sit in the liner and not be directed anywhere.

You are absolutely right. These guys are doing it the way they have probably been doing it since 1980. Obviously they are quite good at the actual work, but apparently have no interest in keeping up with modern techniques…which in the case of pouring a pre-sloped bed for the membrane, is really not that cutting edge…

I agree because as a Plumber in the 80s I never saw any pre slope and I install many vinyl pans with the 4 bolt pvc drain and also 4 bolt cast iron drains for the tile setters as it was in my job classification..I agree with the previous slope reasoning…

yup. Flat pan = mold/mildew factory. Always preslope before installing the shower pan.

Yep

I agree

This looks great. Can the same method be used for installing a linear drain?

Hi, I am planing to build a dog wash station made with concrete and tile. I would like it to be at least 18 inches high. Do I need to poor 18 inches of concrete from the floor to the bottom?, could it be possible to use 2×4’s as a base or concrete blocks and then make on top of it the shower concrete base? I am worried if in the future I want to check the plumbing I wont have access to it since it is all made with concrete. Is it possible to make the shower base with just concrete sheets like you make the walls and then put the tile on it so it is not so heavy for a 18 inch high shower?

Thank you for you reply . I have a lot of questions 🙂

If your interested in a custom dog bath, I’ve built a few. You can see pics on my Facebook @ ZM Construction

Why did you guys use a backer board instead of a mortar mix for the sub floor? What are the pros and cons of each?

Thanks

No pre-slope? Really? Run away! This is absolutely wrong!

Right. No preslope, nothing covering weep holes. Nails should be 4″ above curb not from floor. Nails in wp holding backer on curb. No backing on face of bench for pan liner.

I think it looks fantastic. It’s hard to find tile guys that still pour pans by hand. They did an excellent job. I build my pans the same way. I spent a ton of time reading of different methods of building shower pans. Everyone has a different way, but if you use good tile an grout an some form of membrane I think your good. Water runs down hill be it an 1/8″ or a 1′ of slope, the membrane is a fail safe, not the water barrier. Your tile is. I’ve pre sloped, used wire mesh, plastic membrane, an kerdi, now I pour one pan…no mesh, no membrane, no hardy backer, just green rock an red guard a couple coats on top. It saves 4-600$ in materials an a day or two in time.

I confused how you saved several days.

You packed the pan..then wait a day.

You put on red guard then wait a day

Another layer of red guard then wait another day..

Red quard required 24 hours between coats.

?????..

Of course saving money on an area that has a higher moisture rate than the state of Washington is the key to making a customer happy.😞😞😞😞…

Right. No preslope, nothing covering weep holes. Nails should be 4″ above curb not from floor. Nails in wp holding backer on curb. No backing on face of bench for pan liner.

He said the tile is the waterproofing. Ha ha ha ha ha. Dont hire this guy.

I noticed you guys laid the mortar mix all the way up to the drain, but by doing that you risk covering up the “weep holes” in the drain which are specifically designed to allow excess water to drain out of the shower pan. You should have laid a layer of pea sized gravel around the drain before installing your mortar around the drain area, to make sure those weep holes are clear of debris and can drain properly, otherwise water will just sit stagnant in the shower pan. And I second the other commenter about laying an initial layer of sloped mortar before installing the vinyl shower pan layer, to allow for the proper slope to drain the water towards the “weep holes” in the drain. I’m currently dealing with this exact issue as the builder hired contractors who didn’t know what they were doing and installed everything incorrectly, as well as covered up the weep holes, causing water damage and cracked tiles and grout, after only 4 months of installation. Better to do it right the first time than deal with the mess of demolition and repair that I’ve had to deal with.

Thank you for taking the time to present this step by step. I’ve tiles one shower, but your corner ideas already are superior to what seemed odd to me (fold it–what a lump!). Then pouring it instead of laying hardy-board down–A no brainer! Now I’ll have the slope! I may have more questions as I go, but I appreciate you helping out a “girl.”

Hardie has no structural value. There should be plywood then mud pre slope.

The tile grout and mudbed do little to prevent the water from seeping down tbrough to the panliner. When a liner is installed on a sloped ( from the corners to the drain) surface that water is drained through weep holes below the finished shower floor. Pans on flat surfaces do not leak but a Fouling Space is created.causing Mold mildew and moisture wicking up walls.

Additionally the panliner installation must include corner “boots” shown in the illustratiin where the curb meets the wall. It will leak for sure if this step is omitted.

Finally The pan folds over the top of the curb (as well as seats and shelves) It must slope slightly to the inside of the shower otherwise water seeping through the top of those surfaces will run out onto adjacent flooring instead of inside and onto the weepholes.

All of nails for tacking up the pan must be at least 4 inches up from the floor as well as a above the height of the finished gently sloped curb. Nails on the outside of the curb to secure the pan are acceptable on the front of the curb only

Ditto on pea gravel at drain and prepan must be sloped!

Awesome job! We bathe at the local river but that’s what I doin when I git indoor plummin

I have a few questions. First, when putting a 5:1 mud pack pre slope down, how long does it need to dry before putting the rubber sheet membrane down? I could only find one place where it said 24hrs, but if that is true, then when putting the rubber down won’t moisture be trapped underneath it.

Second question is when putting the final layer of the shower pan down, how long does that need to dry before laying tile?

Also, if I am putting the pre slope / pre shower pan on concrete, do I need to put a layer of felt down first, if not will the remaining moisture then escape down through the concrete slab?

Thanks

I don’t see a prepitch under the pan. This is a must have and the proper way. The water that settles to the pvc pan will sit and cause mildew and calcium deposits (efflorescence).

2nd always build a block seat (or pour cement seat) on top of the pan. Wood framed seats leak. If you put a membrane on top of wood framed seat then you punctured it by screwing the concrete board on top.

Sorry this shower will have issues.

What do you mean by block seat?

1st 4″ up the wall or code…4″up the wall is 2″short unless there is no curb, all fasteners must be above curb. 2nd the pan is there to waterproof, tile showers always weep water to the pan in time. If the pan isn’t sloped it’s laying flat. Minimum slope is 1/4″ fall per a running foot…4 ‘ to drain = 1″ drop/fall from wall to drain making perimeter of shower walls level. There’s more…I’m building by Tile Institute that sets all the codes architect’s/engineers follow.

I was told the same pre pitch the base then the liner but my question is ,isn’t the base done then the backer board on top of that?

That depends on type of backer used.

Thanks everyone, I’m learning something all new here! You guys sound Very Professional and that’s where and whom I like following .

I’m planning a LARGE SHOWER WITH A WHEELCHAIR ENTRANCE!

Any suggestions in that respect is always appreciated!

Bill

Hey Bill,

I definitely recommend that you look into a Schluter shower system. You can have a line drain and a single slope towards the drain removing the need for a curb. Let me know if you have any questions about it.

Screws in curb and no preslope. This will not last.

Hi Bill. I am putting a shower in the basement that has a cement floor and I don’t plan on tiling it. What kind of mixture should I use for the base that won’t be slippery but still smooth to stand on?

How many hrs/days will this whole process take?

While I appreciate your blog and it’s vast goal to help the DIY crowd, you skipped due diligence in researching STANDARD practices. American National Standards Institute (ANSI) has defined limits required within shower enclosures. Pan pre-slope has NOTHING to do with an unlevel subfloor and EVERYTHING to do with removing water under a tile shower floor.The sand mix (accompanied by pea gravel at the drain assembly) are specifically used to move water away. Just because an installer has been doing it the wrong way for 20+ years doesn’t mean it’s right. BTW, the standard for for nails or screws isn’t 4″ above the subfloor it’s 3″ above curb height and the nails or screws should be non corrosive and nonoxidizing and EACH penetration sealed.

The key point is water WILL go through the grout and when it does it is directed through a drain. This post scares me..because of age and incorrect information.. I wonder how many people are now battling mold in the shower pan and worse, in adjacent rooms.

Hi Pat do you need to put mud before liner 10 video say yes 10 say no

think the cement board is going to “wick” quite a bit of water out of the mud bed…we used to leave a half inch gap from mud pan to bottom of backerboard to avoid wicking…that is how we used to do it…now we only use orange…..

Yes backer board should be 1/2″ above pan to prevent wicking I even put a bead of silicone below the backer board as a extra step to prevent wicking

This is great article. Wanted to comment on the pre-slope. They are not required and are a waste of time but do not hurt anything. There is a phenomenon in water / concrete called Capillary action. Water does not drain because of pre-slope but only once the concrete is fully saturated will it get pushed out to the drain. Capillary action. If you have water getting into the concrete and past the liner you have a bigger problem and pre-slope won’tfix it.

We are replacing a fiberglass shower with tile & it has a concrete floor because it was previously a garage that was converted into a bathroom & family room. Can I lay the tile on the concrete floor without using the membrane & mud?

45 years experience. And you do not build your seat with wood . You get water in the shower pan witch crawls under Durock and swells wood. I have made a living because of people like you.

Curb should be mud. I do my pan and curb at same time so it is a single unit.No cementboard on liner.

Good job and good tips,I’ve never done this but I am hungry to learn and try.

I am planning on pour a shower base/pan on a basement concrete floor. The shower Is 60”x 36” with a 5.5” high front curb with the sides and the back 1” lower, then sloping to the drain which is centered. I do not plan on tiling. Just want to leave as exposed concrete. What concrete mix should I use? How do I seal the concrete. Any input would be appreciated.