I’m excited to kick-off another Pro-Follow and to introduce you to a new pro named Danny Riter. Danny is a hardwood flooring contractor and owner of Signature Hardwood Floors Inc. Danny brings more than 20 years of experience in the industry, and he’s very knowledgable. I hope to bring you more Pro-Follows with Danny in the days to come. For this project, the homeowners have brought Danny in to replace a tile kitchen floor and refinish the existing hardwood floors to match.

If your interested in learning more about installing hardwood flooring, follow that link to see our Project Guide for full details.

Danny’s crew will be refinishing a sizable area including three rooms, a hallway, laundry room and several closets. The old floor is a 3/4″ x 2-1/4″ oak, and it’s in fairly good shape. The guys will sand the existing floor down and finish everything (old and new) together for one, consistent look.

If you look closely, you’ll notice the shoe molding has already been removed in these pictures.

Danny’s crew is taking up the kitchen tile and the two layers of plywood underlayment before laying the new boards, and I’m excited to see how they blend the old and new floors.

Step 1: Setup Plastic Barriers

Refinishing floors can create a significant amount of dust so before any work began, Danny’s crew covered just about everything in plastic.

Pro-Tip: Change your furnace filter after refinishing your floors.

These guys were thorough, covering doors, light fixtures, shelves, cabinets, the fireplace, and more.

Step 2: Demo

After the plastic was setup, the guys got started on removing the old tile floor.

When possible, they removed large sheets with the tile still fixed in place.

Some of the plywood extended underneath the cabinets. Rather than pull up the cabinets, Danny’s crew used a handy flush-cutting circular saw to cut through the plywood.

It was slow going but eventually the tile floor was completely removed. As the guys cleaned away debris, they were careful to remove or pound in any protruding nails.

Step 3: Remove Some Floorboards

To seamlessly transition between the old floor and the new floor, the guys need to remove specific floorboards to be able to thread in new ones. Otherwise, the guys would have to incorporate an ugly transition strip.

There’s a couple of different ways to remove a single floorboard. For instance, you can set a circular saw to the appropriate depth and make a series of cuts until there’s enough room to pull the board free. In the picture below, one of Danny’s crew is using a hammer and chisel to slide a board out, and as you can imagine it takes a lot of pounding.

You can see how Danny’s crew is removing floorboards enough to stagger the joints.

In a few instances, the guys used an oscillating multitool (OMT) to carefully cut a board and create a new joint.

Step 4: Begin Laying New Boards

Next, Danny’s crew measured and snapped a chalk-line to provide a reference point. The guys setup the first new board and measured the distance to the chalk line to ensure it was straight.

Pro-Tip: Be sure to let the new board fully acclimate before installing.

After they lined everything up, the guys toe-nailed the first board with a finish nail gun and 16ga, 2″ nails.

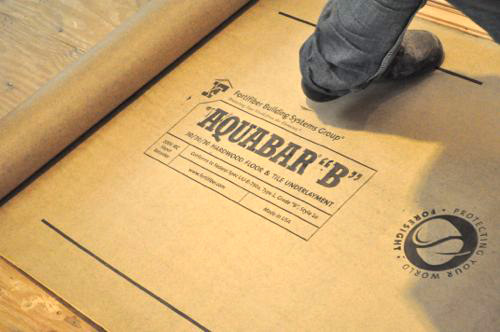

Step 5: Unroll Underlayment

Underlayment reduces squeaks and creates a vapor and moisture retarder. The guys used Aquabar type B underlayment.

Step 6: Continue Laying Boards

Danny’s crew continued laying boards in the field, threading them between the existing floor boards. After three rows, the guys were able to break out a Bostitch flooring stapler to anchor the boards.

Where a new board was directly against an old floorboard (and therefore only able to place a few staples on the open end), the guy used a dab of construction adhesive to help lock it in place.

In this way, the guys began laying new floor boards and “weaving” them in with the old flooring.

On the next Pro-Follow I’ll be covering how Danny’s crew sanded the existing floor to make it look like new so stick around!

“As the guys cleaned away debris, they were careful to remove or pound in any protruding nails.” A great tool for finding protruding nails is a floor scraper. It will snag on the nail heads and then you can bang them home.

Ethan, Can you ask them about cleats vs staples? Why do they prefer a stapler over a cleat nailer? Did the staples break off any tongues?

I asked the guys, and they prefer 2″ flooring staples. They said cleats don’t hold as well and sometimes the nailer can overdrive them. From what I observed, the staples didn’t break off any tongues. Great questions Jeff.

Excited to see these guys work! I prefer hardwoods to tiles in kitchens as well, although I know there are many different opinions out there.

It looks like some walls were removed, and now two vents are close to each-other, are they going to do anything with those vents?

I really don’t like the idea of not continuing the new flooring under the cabinets, especially since the old flooring was under there. How much more would it have cost do do that?

when they were using a chisel to pound out the board… what about the nails?

Hey Joe. They did eliminate a set of vents that was really close to another set. With the cabinets, I think it was a homeowner call. They like their kitchen (at least the layout) enough to commit to it. Not sure about the cost difference- good question. Pounding out some if those boards was slow going. Either the nails broke off or came with it. Either way, the real concern is not damaging the face of the boards since they’ll be re-nailed anyway.

What’s underlayment made of? Never heard of it before.

Boy, I can certainly see why hardwood flooring is so expensive. To have it done right there’s really not many shortcuts you can take

I’ve used red rosin paper before and it provides some moisture and vapor barrier. Plus, it helps eliminate squeaks.

OK, Ethan, now that you are an expect, will you come help us do something like this? We are putting in a new bathroom so we have to move around some existing hardwood flooring. :0D

Haha! Hardly the expert (yet), but I do know a good contractor 🙂

I am surprised they can slide one of the old boards out. Wasn’t it nailed in place?

It was nailed in place! They had to pound it out, and it took some doing.

OK removing tile flooring is one job I would never want to do after seeing this.

I just helped a buddy do it a little bit last night and it didn’t seem too bad… But we didn’t attempt to remove large sheets at a time… just individual tiles

Ethan, was the progress that you’ve covered so far completed in one day? And how many guys does Danny have on his crew?

Hey Matt (I’m assuming this isn’t Jaque), Danny had about six guys working and this whole project took about a week. Waiting in between stains / poly / shellac slowed ’em down at the end. The work I showcase on ‘day 1’ actually encompassed a few days.