Between six and twelve months ago, we poured four separate 250 sq. ft. quadrants of self-leveling cement (a.k.a. self-leveling mortar, or self-leveling underlayment) onto our basement concrete slab. We selected LevelQuik ES for the job and followed the instructions to the letter… Or so we thought…

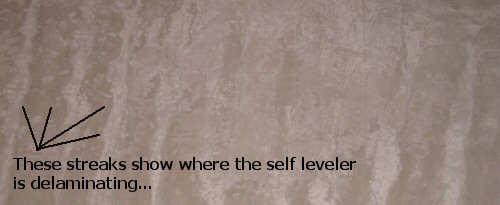

Much to my dismay, last week I noticed that a small 3 foot x 8 foot area of the underlayment had an issue. The top 1/16″ of the self leveler was partially crumbling and delaminating from the surface. There was a significant amount of dust in the area and loose cement bits. The issue isn’t systematic across the whole floor. In fact, this section is in the most recent quadrant poured, while other areas over 12 months old are working out just perfectly. We’re getting ready to insulate the basement and soon after, lay Schluter Ditra and stone tile.

What Causes Self-leveler to Fail?

Before we started the project, we googled extensively for advice on using self leveler on a concrete slab, unfortunately finding little. We’ve subsequently written a great deal about our own experience with self leveler (much of it at that link). Even though information was a bit sparse, we heard repeatedly from tile experts that you must follow subfloor preparation instructions, you must mix the self leveler to the consistency on the package, and you must follow application instructions. We did all that, so what caused the issue?

Unfortunately, we’re not sure. Perhaps one of the last batches of self leveler wasn’t completely mixed, or some contaminate got into the batch, or the water/powder ratio wasn’t quite right. Any of these could have caused the problem. We’re pretty sure the subfloor isn’t part of the problem, since the delamination is limited to the top 1/16″ layer.

Our Solution: Prime the Area with LevelQuik Primer

LevelQuik Primer is a latex-based primer designed to prepare a surface for pouring LevelQuik on top. We noticed in using this primer on other sections of the subfloor and existing SLU that it tends to bind up any loose dust on the LevelQuik and create a smoother surface. We applied full strength primer to the 24 square foot area and, for now, all is well. This solution seems to have worked. The surface layer appears to be stable, and we’ve noticed no further delamination.

Other Self Leveler Problems & Solutions

We’re lucky that this problem isn’t systematic across the floor, or all the way to the slab. If that were the case, the only solution would be to remove the SLU as much as possible, correct the issue (if it is subfloor related), and re-pour the area. Since we’ve got radiant heating wire in the way, that would prove very, very difficult.

For those of you out there considering this project, remember: subfloor preparation and following application instructions is absolutely essential.

What do you think? Ever had a problem with self-leveler, or looking for advice on working with the material? Leave a comment here, and don’t forget to use the site’s search function. There’s a lot of good information available.

Fred,

Couple of things come to mind (my graduate research was on cementious materials) with your problem.

1. I think part of the issue here is time. I think most self levelers are meant to be installed and shortly thereafter a finished floor installed over them. I say this because in order for self levelers to do their magic they have to be a very high water/cement ratio. High water/cement ratio’s are notorious for causing flaking/dusting/shallow spalling in concrete and mortar. I wouldn’t worry too much about it. I think what you did with the primer should stop the problem.

2. It’s likely that your final batch had a higher than normal water/cement ratio which caused this issue. I think the thin set will react with the SLU and take care of the problem once you put the finished floor down.

I wouldn’t loose sleep over it!

I’m having issues with this right now! We put a concrete subfloor in our bathroom (self leveling quick set – I think, though my FIL did it, so I’m not really sure) and tiled over it, but they weren’t all even – some were higher than others, and within a year, one of the tiles cracked. We started over by having the tile and mortar removed and are now trying to repair the concerte subfloor. I haven’t bought the self-leveler mix yet, but I’m assuming that’s what I need to do to repair and prep the floor for tile. Or do we have to tear out the entire concrete floor and start over? The floor is basically level from one end to the other, but the texture of the floor is very gritty and rough with little peaks and valleys. I think the self-leveler will fix this, but am not sure.

Todd – Thanks for the encouragement. I’m going to prime the entire floor in the next 10 days, I’ll let you know how it turns out… but I think you’re right… My biggest concern is to keep the radiant wires protected during insulation and drywall.

Liz – is the concrete floor you’re talking about a new addition on ground level where a concrete foundation was poured? Or did your FIL pour self leveler over the slab or a second floor sub-floor? How did you remove the tiles? (hammer?) How to you remove the thinset the tiles were set in? Is the roughness some of that powder?

The big issue with self leveler is getting it to bond to the subfloor (whether concrete or plywood). Self leveler will definitely give you a smooth surface, but it might be overkill.. You described the surface as “rough and gritty” but with peaks and valleys… can you sand the surface to get it flat? Is the surface deteriorating?

Hey! My husband and I are really enjoying your blog. We recently began getting into home improvement projects including tiling his “man cave”. The floor was not level so we primed and laid down the self-leveler. We poured it in several batches – the final batch over 2 days ago. But a small portion is still wet and there is the chalky area around which I’ve ascertained is probably due to too much water in that batch. My question is if we can prime over the wet portion of the self-leveler. It’s been nearly 72 hours and it’s still soaking wet! It’s not the whole batch – just about a 2 feet square section. What should we do? Thanks for your help!

Hi Jennifer… thanks for reading and for the question. If the area is limited to a 2×2 square and it looks weak (if it was still wet after 72 hours, that’s a problem). I would probably try to dig it out and re-pour the area… Has it set up any more in the last 48 hours? I would guess the cause was an improper mix or too much water in the mix (you have to be really precise with levelers).

I have a partially finished basement and my concrete floor is uneven. I want to level the floor out and instead of putting a finished product such as tile or laminite. I want to paint it with an epoxy paint specialized for concrete. Is this safe because I was told at a hardware store that the self leveler would eventually crack and no self leveler would adhere to cured concrete no matter what anyone says.

cortney–

Hardware store is wrong. You can definitely do this. See this video:

https://www.oneprojectcloser.com/mix-self-leveling-consistency-thickness-underlayment-levelquik/

and this post:

https://www.oneprojectcloser.com/self-leveling-underlayments-achieving-level/

and this post:

https://www.oneprojectcloser.com/self-leveler-for-tile-over-a-large-area/

Good luck!

I have an ongoing basement project going. I insulated the walls and put up drywall before ever realizing this as an option on my uneven floor. Do you think there would be any problem with applying the self leveling compound up against the drywall? Should I put up a temporary barrier to leave a small space between the concrete and the drywall?

Fred,

I am having a similar issue with SLU. It has been 48 hours since we poured it and most of it is hard like cement. There is an area going across the bathroom floor that is darker and I can press my thumbnail in it. I did put one 18 x 18 ” tile in that area before I realized that it was soft and kind of crumbly.

Did the primer solve your issue? This is poured over RPM mats (rpmmats.com if you would like to see the video) and for me to try and take some of this out will be very troublesome. I am wondering if it will get hard over time. To a certain degree, I think I will be okay, because as you see in the video, these studs hold most of the weight. They are very strong (holding tons they say).

This is quite an investment and I would love to think that Todd’s suggestion would be true when he says “I think the thin set will react with the SLU and take care of the problem once you put the finished floor down. I wouldn’t loose sleep over it!”

What do you recommend?

Hello Jerry,

How is your floor tile now? I have the same issue you described and really do not want to take out all of the SLC. The floor is solid but I can scrape it with a knife but not with my thumbnail.

We had a self leveling compound poured onto our basement concrete slab 8 years ago. The company, Accufloor, cup ground the old slab first, then pumped in the SLC. The surface looked fine so we proceeded to tile the basement floor with porcelain tile. After a humidifier leaked in the basement, our tiles started to pop up. We’ve now had to have the basement tiles removed and are wondering what to do with the SLC underlayment. The top 1/4 inch is chalky and white. Some areas are completely disintegrated. Do we need to remove the entire underlayment and go with a mortar bed instead? Is any kind of SLC appropriate on a basement slab? Isn’t there always some moisture present in a basement slab?

We’re also considering in floor heat now that we have to re-do the tiles.

Thanks for the advice!

I am refinish a bathroom. I use backerboard on the floor. I still have uneven spots, enough that the tile lays uneven. Should I use self leveling compound or thin set to correct the problem.

Paul

Paul, if it’s not terribly uneven, you can level things out with thinset. If it is VERY unlevel, you probably should have addressed it before putting down the backerboard. I wouldn’t recommend using a self leveler unless things are REALLY unlevel over a reasonable sized area. You’ll need to add at least 3/8 inch to get a good bond. You will want to use a primer on the backboard first, too.

I pour self leveler on a small bathroom floor (5’x5′). The leveler bubbled and within 24 heaved. It appears attached on the edges. The concrete has a white material over a portion of it. I did not use a primer because the hardware store told me it wasn’t required for the product they sold me. Any thoughts what happened.

Another great post!

I had a project several years ago where I needed to re surface an area. So, I/we decided to use a colored epoxy type material. We had a similar situation occur. Dont know why or how it happened as we to followed directions to the t. Thanks for your input and suggestions to these issues. Dave

No! The self leveler is not fixed by the thinset. The proper way to set anything on anything is to make sure the cement or self leveler is sound. From unwanted and expensive experience. Proper way is to generously use primer. Role it on and make sure it’s enough to penetrate the concrete. This is essential to having the self leveler bond to the floor. If it is flaky or cracking or Sandy, scrape it up and redo it making sure you have enough primer on 1st. Otherwise your tile will pop up and you will have a large and expensive headache

Dealing with crumbling self-leveling cement can be frustrating, but there are several steps you can take to address the issue:

1. **Assess the Cause**: Determine why the self-leveling cement is crumbling. It could be due to improper mixing, insufficient curing time, poor adhesion to the substrate, or other factors. Understanding the root cause will help you choose the most effective solution.

2. **Remove Crumbling Material**: Use a chisel, hammer, or scraper to remove the crumbling sections of the self-leveling cement. Be thorough in this process to ensure that you remove all loose and damaged material.

3. **Clean the Surface**: Once the crumbling material has been removed, thoroughly clean the surface to remove any dust, debris, or contaminants. This will promote better adhesion for the repair material.

4. **Prepare the Repair Material**: Prepare a new batch of self-leveling cement according to the manufacturer’s instructions. Make sure to mix it thoroughly and achieve the proper consistency.

5. **Apply the Repair Material**: Pour or spread the prepared self-leveling cement onto the cleaned and prepared surface, ensuring that it fills the voids left by the removed material. Use a trowel or a similar tool to smooth and level the surface as needed.

6. **Allow Sufficient Curing Time**: Follow the manufacturer’s instructions for curing time. It’s essential to give the repair material enough time to fully cure and harden before subjecting it to any weight or stress.

7. **Consider Sealants or Coatings**: To provide additional protection and durability to the repaired surface, you may consider applying a sealant or coating specifically designed for self-leveling cement. This can help prevent future crumbling and enhance the overall longevity of the repair.

8. **Address Underlying Issues**: If the crumbling self-leveling cement was caused by underlying issues such as structural instability or moisture problems, it’s essential to address these issues to prevent recurrence. Consider consulting with a professional if necessary to identify and remedy any underlying issues.

By following these steps, you can effectively deal with crumbling self-leveling cement and restore the integrity and functionality of the surface.