We first ran this article in 2010. It provides detailed instructions for installing hardwood flooring over a wood substructure. It chronicles tutorials for each step of the process, derived from our installation of 3/4 inch solid, tongue-and-groove Brazilian Walnut hardwoods in our own home!

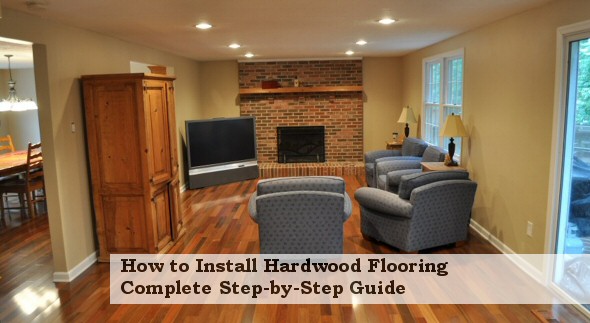

At the bottom, we provide links to posts on the tools we use and frequently recommend for hardwood installation. Below is one picture of the final product. Here’s the rest. This project was a lot of fun. We hope you enjoy the tutorial!

While each hardwood job has its differences and subtleties, this series covers many of the common challenges and pitfalls inherent in every hardwood installation, from leveling the subfloor to installing baseboard and shoe molding. Just follow the links in the steps below, and don’t worry – no spam here. This is just straight-up content!

We hope you enjoy the series as much as we enjoyed publishing it! We also hope it’s helpful to you in your project. Before we get started though, just a reminder that the content is provided without warranty, and as with everything on our site, use this information at your own risk. We always take care in describing the steps and precautions for a job–and hardwood is a relatively safe subject–but there is always the possibility we’ll omit something important.

Not Doing it Yourself?

Before we get started, if you aren’t doing this job yourself, we partner with Home Adviser for free quotes. They match homeowners with screened and approved local contractors who can get the job done right. Here’s the link:

Steps to Install a Hardwood Floor

(hover over the links to learn more about the article)

Step 1 : Planning Your Floor

Consider what subfloor material you have (plywood or OSB) and its width, which may influence the direction you choose to lay the hardwoods in the room – either perpendicular or parallel to the joist substructure. Note: for concrete slab installation, engineered lumber is a better choice than solid hardwoods. Hardwood installations are most stable when they are installed perpendicular to the joists; but if your subfloor is sufficient, a parallel installation is acceptable.

Step 2: Preparing the Subfloor

Step 2: Preparing the Subfloor

Ensure the subfloor is sufficiently level for installation–there should be no rises and falls more than 3/16 over a 6 foot span. There are several ways to level an uneven subfloor for hardwoods.

For systemic problems, a good alternative to complete replacement is leveling the plywood or OSB subfloor using asphalt shingles. This method relies on shingles and an additional layer of plywood to get uniformity across the floor.

If a subfloor is high in a single or few locations, you can pull the subfloor up and plane the crowning joist to level the floor. If a subfloor is low in a single spot, you can pull the subfloor up and shim the floor, using a similar approach. If you decide to plane a joist, remember that this could have an affect on the structural integrity of the floor and it is important to get the opinion of a structural engineer. In any case, reattach the subfloor with screws and construction adhesive.

Step 3: Acclimate the Wood

With the subfloor sufficiently leveled, acclimate the hardwoods in the space where they will be installed. Leave the hardwoods in this location for 7-10 days. Make sure not to stack the boxes, and run the A/C or heat normally. The best time to install hardwoods is the Spring and Fall when the humidity and temperatures are at yearly averages, but Summer and Winter installations are possible with the proper precautions. Never store the hardwoods where they can get wet.

Step 4: Laying the First Row

When the hardwoods have been properly acclimated, it’s time to lay the first few hardwood boards. The first board in an installation sets the tone for the remainder of the installation. Take time and do it carefully. That article covers every step precisely.

If installed properly, the rest of the floor will practically lay itself. If installed unevenly, gaps will develop as you lay subsequent boards and you will be frustrated with the result. It is here that the technique known as blind nailing is first used.

Step 5: Laying Hardwoods in the Field

Continue laying hardwoods throughout the floor. While the bulk of a hardwood installation is tedious but uncomplicated, there are a few areas that can be challenging, and we have articles to cover these situations:

- (working around vents) Most modern homes have at least a few HVAC vents located on the floor. Laying hardwood around vents is simple, involving only a few measurements and cuts with a jigsaw.

- (working through doors) When maneuvering through an installation, you will likely have times where the hardwoods go through a door. When this happens, you should cut the door trim and stops just high enough to rest at the new floor level.

- (working around walls and obstacles) When laying hardwoods around a wall or when going around an object, you may have to start a new first board against the back side of a wall. When this happens, you should follow all the steps involved in laying the first board.

Step 6: Laying the Last Board

When you get to the last few boards of the hardwood installation, you will need to blind nail and then face nail the wood because the hardwood flooring stapler or nailer will not fit (article coming soon).

Step 7: Flooring Transitions

After the floor is laid, you’ll likely need to transition to adjacent rooms and flooring surfaces, or install stair nosing. We discuss the proper place to transition in a doorway in our article on working through adjacent rooms. (other articles coming soon).

Step 8: Trim, Baseboard, and Shoe Molding

Install baseboard and shoe molding around the perimeter of the floor to ‘frame out’ the room. This involves scarf joints, inside corners (which can be cope cut), and outside corners. Quarter round can be an acceptable alternative to shoe molding if you have large gaps.

In fancier designs, three or more baseboard components are used, but in the typical installation only two (base and shoe) are installed. There are been a lot of discussion on our site on whether shoe molding and quarter round should be stained to match the floor or painted/stained to match the baseboard. If you are installing an exotic hardwood, you’ll find that the trim components are expensive. One alternative is to stain pine quarter round or shoe molding to closely match the floor.

If you’re laying next to kitchen cabinets, you should pick a shoe molding that matches the cabinets as opposed to the floor.

Tools to Install a Hardwood Floors

For a job this large, we were happy to have DuoFast sponsor the primary tools, providing their DuoFast Floormaster 200-S Hardwood Stapler for the bulk of the floor. In our 1100 square foot installation we fired nearly 3000 staples, or an average of just under 3 per square foot. The Floormaster 200-S performed flawlessly, with no jams.

DuoFast also provided their new DuoFast Floormaster 250BN finish nailer for the first and last boards and to facilitate molding installation. Both of these tools performed very well across our floor and we’d highly recommend them to folks installing flooring in their own home.

Where to Purchase Hardwood Floors

The flooring used in this installation is Lumber Liquidator’s Bellawood Brazilian Walnut Flooring. Bellawood is an excellent product sealed in many layers of aluminum oxide, the best surface coating for hardwood flooring. Aluminum oxide is far superior to polyurethane; it has better scratch resistance and does not fade or yellow over time. If you haven’t purchased your flooring yet, we highly recommend Lumber Liquidators online web site. Their site features really good deals and they can ship the product directly to your front door.

Hardwood flooring is offered by several other big box retailers and can be a significant investment. If you don’t choose Lumber Liquidators for your purchase, consider Lowes. We’ve written about a free Lowes Coupon that can save you 10% off a major purchase like hardwoods.

Did You Find This Guide Useful?

If you found this guide useful, we’d really appreciate it if you’d click the Facebook “Like” or Google “+1” buttons over there on the left. They let others know that these guides are helpful! Thanks so much!

What do you think? As with all our articles on this site, help us make this better by adding your own suggestions and thoughts!

I think you have a typo. You said, “The best time to install hardwoods is the Spring and Summer when the humidity and temperatures are at yearly averages, but Summer and Winter installations are possible with the proper precautions.” I think you probably meant Spring and Fall, not Spring and Summer. Thanks for the great website!

I am installed per-finished h/w floor on the 1st floor. I have a sunken Living Room. It needs a bullnose from DR to LR. when installing HW in the DR, should I base everything on the bullnose? Meaning, lay everything so that everything aligns with the bullnose even that means trimming the 1st row so everything will line up correctly. Hope this make sense.

A quick response is apprecaited since I am ready to begin installation.

Thanks in advance.

David, good question. Simple answer is yes, you should base it on the bullnose if you don’t want to make rip and route cuts on the last piece. Whenever I can start a floor at that point, that’s what I do.

I have a room with baseboard down but no flooring or quarter-round. Must I remove the baseboard to lay a 6-inch pine tongue /grove floor (new)?

It all depends. As long as the baseboard allows for expansion of the flooring you should be fine. If it doesn’t – like my recent project didn’t – then you have to remove it and re-install it with clearance for expansion. Otherwise you will have problems in the future.

Thanks for a thorough guide. I’ll still probably hire a professional, but it’s good to know what goes into it.

Great article. If you can’t follow this, then you should definitely hire a professional. Either way, great information. Thanks.

When should/shouldn’t you glue? Does it matter how wide the board is or the nail guage?

Also, do you have any tips on covering stairs with hardwood? Would you suggest the average DIY’er try covering stairs?

MD – Generally speaking, I don’t like glued-down floors. They are much harder and messier to remove and more difficult to install than stapled floors. However, these floors tend to be installed over a flat slab. You would use engineered wood as opposed to solid wood when gluing because it is dimensionally much more stable. You also glue down treads when building stairs, and you can use glue in some situations where a finish nailer wouldn’t reach.

I generally advise against DIYers doing stairs. They are complicated to get them looking perfect. One of our sister blogs, Centsational Girl, has a good tutorial on hardwood stairs. http://www.centsationalgirl.com/2010/10/the-risers-and-the-treads/

This is one thing I couldn’t do correctly, my study room project become a horror experience.

Hello, I have a problem. A water line broke in my house and the Insurance is paying for the floor to be replaced. The problem is that my flooring is enginered and 3/8″ thick. It is glued onto a subfloor and below that are the enginered trusts. I have one contractor that wants to remove the wet wood. Then staple and glue the new floor to the old flooring. His issue is that ripping up the old floors will damage the sub-floor and possibly the trusts. causing bigger problems. Any thoughts….

Dennis, I doubt that ripping up the floor will cause substantial damage to the subfloor, and I’d seriously doubt damage to the underlying trusses…. I wouldn’t rule out subfloor damage as a potential problem, though. Wouldn’t your insurance be forced to pay for a subfloor replacement if they’ve already agreed to replace the floor and the issue runs deeper than the surface floor?

Great article – we are having harwood installed this week and even though we have hired a contractor to do it reading this will allow me to understand and follow what they are doing.

I have a sunken bedroom where we are having hardwood floor installed, my question is: How do I run the wood floor along the wall of the sunken bedroom.

Teresa, take a look at the section on leveling a subfloor, and especially the method for using asphalt shingles. You may be able to run shingles close to the wall to get it level. Feel free to ask some more questions on that page.

I have a question. What is the best wood floor material that does not stain when you spill water on it? That is really my problem on my old wood floor.

I am preparing to install 3/4″ pre-finished red oak over a plywood subfloor. Is it advisable to install some type of expansion joint since the flooring runs from one end of the house to the other, approximately 80′? Also I have three rooms that are over 25′ wide.

I am installing pre-finished h/w floors in our DR and LR. The LR is stepped down about 8 inches from the DR. I’m using a bullnose, which is 12 1/2 ft long, on the edge of the DR floor. How do I transition the baseboard and concave shoe molding from the DR down to the LR and going around the bullnose.

Greg, this really depends on the room itself. Can you send me a picture at fred@oneprojectcloser.com and I’ll take a look?

I just got done installing a maple floor in our office and I referred to the information in this article extensively. Thanks for a thorough, well documented tutorial – it made my job much easier!

Music to our ears! Thanks so much for the positive feedback!

I was wondering if anyone has ever installed wood flooring in a kitchen over 6″ quarry tile? any help or direction would been great.

I would have to think that #6 and #7 are the most important parts of the floor. Most anyone can get the floor down and make it look nice. However, to finish it off nice and make it look professional is another thing. It’s not rocket science but a little planning a few feet before the end is super important. Looks like you guys did a fantastic job on this one. Nice work!

Great information Fred and what a beautiful floor you installed. Very professional looking too. I didn’t see where you mention the paper that’s placed over the sub floor. The pink stuff. We had some tar paper left over from another project so instead of discarding it we used it.

My hubby started with the upstairs hallway which has right angle turn. We both agreed it would look best if the boards ran the length of the hall in both sections so I suggested making the corners like a log cabin quilt. We also did it around the very edge of the hearth in the Gentleman’s Parlor and as a large boarder in the Ladies Parlor. We laid the boards in the Library at a 45 degree angle.

Oh and “we” meaning I was just the planner and gofer, hubby did the actual installation.

Not sure this link with work, but here’s some pictures I have of our floors during and just after they were installed.

Our Floors

I don’t know why its taking me so long to reply to this one, but your floors look great. I love that log-cabin design in the corner – its something we considered on our first floor until I got intimidates with the work. I was thinking about running a perimeter around the whole floor and then laying the wood inside of it… never got there, just seemed too hard!

Hey Fred. Glad you liked the floors. My hubby is amazing when it comes to trying new things since we started to build our home. He said the log cabin corners were quite easy. However he was intimidated at that thought of making bookcases for our library. Finally I took him into our walk in closet and said, you did this according to my drawings and it’s basically the same concept a bookcase would be. The bookcases are coming long beautifully.

Love this post. In our new home, I am trying to decided whether to keep the carpet around or not. Have you ever left one particular room carpeted and done the rest of the floor? or does it make more sense just to do wood throughout and use a huge rug or something?

Yep, we’ve done that very thing in other homes, or left an area with hardwood and and area with tile. There’s really no “Rule” per se, but here’s something to think about: A single flooring surface across an entire level of a house makes the rooms feel much, much bigger, because the natural boundaries between the rooms is removed. So, when you stand in the dining room, it looks like it extends to the kitchen, or family room, etc., because there is no division. Likewise, when you stand in the kitchen, it looks like it extends into all the adjacent rooms. That’s why open floor plans have become so popular–because they make the same square footage home feel bigger than if it were divided (either by walls, or paint colors, or flooring surfaces).

We’ve become big fans of the hardwood-and-rugs motif for our home. If we want to have a cozy area, we simply get a thick rug and put it in that room!

Overall, fantastic guide. I have about 6 tabs open right now going through the details of all the steps. At some point in the next few years the wifey and I are gutting the kitchen, taking out a wall or two, and then hardwood throughout the kitchen, dining, living room, and stairs. I’ll be going over the guide again then.

What’s a kerf joint? You mentioned it in Step 8. I’ve used scarf joints when doing long trim runs but not sure what a kerf joint is.

I am not sure, I think they meant scarf joint (they called it a simple joint in the tutorial).

When you said kerf joint I was thinking about the double grove & spline joints you need sometimes to switch directions… but thats not it either.

Online search yields that some call a mitered spline joint a kerf joint. A spline fits in the kerf left by the table saw or router. One of my future projects is making sled for the TS to do both straight splines and dovetail splines for decorative boxes.

I found those too, looks like a good way to make a miter joint stronger (like a poor mans biscuit joiner).

It should have been “Scarf” – My mistake. And I knew about that one too and for some reason never fixed it. It feels like maybe this is an older version of the post, but that could just be my old age showing through 🙂 A Kerf joint does exist, as you point out Jeff, but it isn’t this joint.

I will reiterate the comment someone made above about spring/fall (you said spring/summer in the article).

Also, the suggestion of cutting baseboard a little long applies all the time, the compression at the ends is good and keeps everything tight.

Joe – two good tips. I fixed the post and I thought I had *already* fixed it a long time ago (on the Summer/Spring thing).

someday I’m gonna read through this & all the comments and take on this type of project for our condo, because everyone has quoted us $6000+ to do it.

Fred,

As others have said, thank you for taking the time to post your flooring adventure and respond to the many questions. The timing for stumbling upon your website was quite fortuitous. I have 3/4″ x 3 1/4″ Brazilian Walnut on order, but am really stuck on some of the basic points before installation even begins.

I am unsure whether to go with staples or cleats. Many people warn against staples with the hard exotics and the 15 1/2 gauge with the Duo-Fast is a concern. If I go with cleats, it looks like I am limited to 1 3/4″ with the recommended 18 gauge cleats. I would like to use 2″ since I intend to have 1/4″ cork underlayment to build up the floor to existing trim, molding, and adjoining floors. I have 3/4″ OSB as a sub-floor and would like as secure a floor as I can get.

Did you have many split boards or tongues? Did you use 2″ staples? Any other thoughts on the nailers/staplers?

Shawn, I HIGHLY recommend glue-tipped staples, just like we used for this floor. We had tongue splits maybe 2-3% of the time, but virtually NONE of those splits prevented the next board from being fastened. We literally fired about 3,000 staples into our floor and it is VERY tight. The floor does not squeak nor move. I am very happy with the choice. The staples give you two fasten points for every drive. The glue heats up with friction on the drive and the lock is VERY tight.

Anyhow, it’s not that I’m an apologist for Duo-Fast or their staples. They provided those for free and I’d tell you if they sucked. But they didn’t, and I’m still very happy with the floor.

Word to the wise, though: Be sure to fully acclimate your floor. We have some gaps… I’m currently considering a whole-house humidifier to try to even out the humidity throughout the year. The floors still look great, I just wish they were perfectly tight.

Our older oak hardwood floors have notable gaps where some of the end pieces come together. Are there any simple ways to improve the looks?

Thank you for posting these detailed instructions-I’m pinning them and considering trying to install myself-but I’m a little nervous!

I have been considering the Brazilian Walnut floors but was worried that they would be to dark. Has your floor darkened up since you took those pictures? Also, where did you get the floors? Your floors look beautiful and just the right color.

Cindy – very very mild darkening, if any. Still look as good as the day they were installed. We purchased ours from Lumber Liquidators. Thanks for stopping by our site. Hope you’ll be back!

I have a computer room, a foyer, hallway, and sunken living room that I’m thinking of redoing with wood flooring. I’m afraid the sunken living room will end up looking like a wood box. What’s your opinion? Any suggestions?

Janice, I can definitely picture what you’re thinking, and I don’t think you’ll be disappointed with the finished look. I assume that the sunken living room has some type of step down into it? The real question is whether you’ll use wood for the riser of that step or not. I think that even if you do, you can’t go wrong with a completely solid wood step system and sunken room. You can break up the space with furniture and accents just fine, and as long as you use a quality wood, it will actually look really nice.

I installed two bedrooms using these instructions and came out real good considering I am not the most skilled craftsman.

Benjamin Raucher

Benjamin, there’s really no better comment than one like this. Music to our ears. Thanks for leaving it.

I am installing 3/4 Hickory flooring in my dining room and kitchen there is a 4′ walkway between the two. The living room is the largest room so I am going to start there. However when I go through this 4′ opening there will be 6′ on one side and 4′ on the other how do I continue my flooring in the kitchen? as far as nailing do I havew to reverse the boards?

Mickey, I think I understand your situation, and a reversing spline is exactly what you want. Basically it’s a “double-tongue” that will allow you to switch directions when laying the wood.

I’m planning on putting Brazilian Cherry in my kitchen and have 1967 linoleum which can’t be removed. It’s a very stable, level floor so is it ok to put the wood floor over this surface?

Melinda, while my first choice would be to pull up the linoleum, it may work to leave it. You really need to drive a few staples and see what happens – i.e. are they going deep enough to hold the wood? I recommend using staples with heat-activated glue on them (the friction during the drive creates heat, which gives you a very solid hold.

Fred–I have a house where the the downstairs (except kitchen) has 3/4″ pine boards (6 ” wide) on the diagonal as a subfloor, with 3/4″ oak t & g (1.5″ wide) over top and perpendicular to the joists. However, in the kitchen they actually framed the joists up 3/4″ higher than the rest of the house, and layed 3/4″ t & g pine boards (3″ wide) perpendicular to the joist. This made the pine in the kitchen and the oak in the rest of the house on the same level. Linoleum tile was laid in the kitchen at some point. I want to run oak in the kitchen, but don’t want that big of a height difference. I was given the options of using a 3/8″ oak over the existing pine; removing the pine and installing 3/4″ oak without a subfloor, or removing the pine and using a thinner plywood subfloor with the oak over top of that. What are your thoughts on this? Do you have any issues with a 3/8″ oak product (trying to stick with the 1.5″ wide)? What should be a minimum subfloor thickness if I remove the pine (if any) and go with a 3/8 oak? What about with the 3/4 oak? Thanks for the blog and your help!!!

Bill, lots of questions here. I hate it when builders do things like this — it makes it very hard to remodel the floor, as you’re discovering.

1) I think if the subfloor is stable, you’re probably OK with 3/8″ wood on top. I would try to find an engineered floor if you are going 3/8″ (engineered does NOT mean laminate… it is still real hardwood on top, its just more stable).

2) I can’t give you advice on a subfloor thickness without knowing the joist spans and center widths. There are a few online resources that can give you minimum spanning for subfloors.

3) I am not a big fan of laying tongue and groove directly over the joists. If you do that, every board needs to end on a joist and its a lot of work. If you have any contraction in the boards after laying them, you might be able to see through the floor.

I think if I were in your situation, I would probably just stick with the 3/4″ pine and look for an engineered 3/8″ oak for the top layer…. You might be able to go down to 5/8″ OSB or plywood rather than the pine, but thats a ton of work to save 1/8 inch….

when building a new kitchen, can you install base cabinets over new hardwood flooring?

Most definitely. In fact, it is far easier to install the hardwoods before the cabinets. It will look a lot nicer!

so if you are replacing a floor that has a cabinet on it (Kitchen is open to dining room and the base cabinet has a granite top making it an island), you should remove all of that instead of working around the structure, correct?

I am putting in white oak in living room where joist run east west so board will be north south. Tv room joist are north south. Plan to go east west but concern about how it will look, adjoining rooms with 2 directions board. what do I do at the point of direction change?

Also base of stairs is curve at one end. What is the solution? someone suggest pastic qtr. round

Layout question. I have a new house that I will be installing unfinished 3/4×5″ pine. There is a great room the width of the building (perpendicular to the flooring)on one end with a hall (running the length of the flooring) connecting back to two bedrooms all to be covered with the same flooring. If the flooring is started by dimensioning back from a center line in the hallway to a common mark on the outside walls in both rooms, one would say they should come together once you reach the hallway. The likelihood of that happening is slim. If it is off an 1/8″, it may as well be off 3″ in the quality of the job. With a floating floor I could make it adjust. Not here. I am thinking of starting in the hallway and going out opposite directions to assure a tight fit in the hall. That means face nailing one course through the center of the hallway. Ugh! Any suggestions?

Chuck, hard for me to picture your situation – but why do you have to face nail any set in the middle? Couldn’t you temporarily screw in a guide board next to the first course to serve as a backstop and then toe nail that board and a few extra courses, then unscrew that guide board, put int a reversing tongue, toe-nail on that side, and then work out from the center?

Thanks for the reply Fred. That is what I was going to do. Start from a center line in the middle and go out both directions. For the one side I can do as you say. Set the first course with the grooved edge on the center line, blind nail it and install the rest of that side out from there. But when it comes to installing the floor to the other side of the center line, I will have back to back grooved edges to start out. So the issue is pinning down that grooved edge when starting the second half of the room. As I see it, I will have to face nail the grooved edge of that first course. I suppose an alternative would be to make a spline to install in those grooved edges to lock down that first course.

Another question. This is a new house with a 3/4″ plywood deck over a full basement that is conditioned air space. With 3/4″ x 5″ unfinished pine flooring, should 15# felt be used under the flooring or would red rosin paper be adequate? Or is there another recommended material? Thank you.

Hi! My husband & I hired a contractor to build a new home due to our previous home burning to the ground with a total loss of everything. We foolishly hired a “friend” & among other issues, he went over on his bid $100,000. On a two bed,2 bath home on land that we owned. My question is this: The contractor picked the installer for our hardwood floors. In less than 2 yrs, these floors, located in kitchen, great room, and hallway are looking terrible. They are separating (you could easily fit a file folder in the “grooves” between the wood. After several repeated calls over the last yr., the hardwood floor installer finally came to look at them, and said it was just normal. He said the separating in the hallway was because it was over the support beam in the basement. He said the separating in the kitchen, dining room and pantry was because there was a refrigerator. This is the 4th new home I have contracted (different builder/different subs), but the first time I have had any problems with my hardwood floors. Should I just forget about it and realize that I will loose money if we ever sell? Or should I push further? I am so concerned with how they look now…I fear about another yr. or more. Thank you so very much for reading and any advice that you can offer!

Hi Bren,

Well the good news is that you probably won’t continue to see the gaps get bigger. After two years the wood is likely acclimated.

It sounds like the problem was with poor acclimation prior to installation. Another problem could be that the wood wasn’t fully dried by the manufacturer.

Hard to know what recourse you might have.

In Maryland, we get a 1 year warranty for home improvement work. After that, we’re on our own. I would check for what the law is in your area and what warranties you were provided.

In any event, in a proper installation you won’t have any significant gaps in the wood. One option to solve some of the problem might be a whole house humidifier. A friend of mine recommended that to keep the humidity from dropping precipitously in the Winter, which can help close some of the gaps in the wood.

The best option going forward is probably to either pay to have them refinished (unless you can get some legal relief from the courts). The refinisher can sand off the finish, fill the gaps, and re-seal the floor. Note, though, that gap filling is *somewhat* noticeable. If you care a whole lot, you’re looking at an entire tear out and re-lay….

Best of luck.

Fred

I have Shaw prefinished 3/4″ Oak getting acclimated in a great room. It measures consistently 6% MC and has been in the room a week. The plywood sheathing of this 34 year old house measures 8 – 10 % MC around the floor. All painting and texturing are finished and I wait. I have an extra layer of visqueen in the crawlspace and it is properly ventilated. Why is the MC so high in this old plywood and at what differnece can I start laying the material? If the wood stays at 6% is a 2% difference acceptable or should everything be the same MC?

Thanks

Roger, I’m not qualified to answer this question, so I’m not going to venture a guess. My gut is that I would want a perfect match between the floor and the plywood. 2% probably isn’t bad, but when they equalize you could get the boards popping out of place. Sorry – wish I could help more.

My husband and I hired someone to install our hardwood floors. Something came up, he can’t finish the job. However, he was running the wood in the hallway parallel to the hallway. Now that my husband is doing the job he is not happy that he will have to face nail at least 3 rows because the staplegun is too close to the wall. Any suggestions?

You’re going to have the face nail eventually. You might be able to get away with just the two last rows if you use a finish nailer at an angle on the third row.

Would it be recommended to install hardwood floors the way the joists run or is it imperative to run the floor perpendicular to the joists?

Don, read this: https://www.oneprojectcloser.com/lay-hardwood-floors-across-joists-or-parallel-to-them/

We ripped up two piece baseboard in a home built in the 60’s. It was 3/4″ square board with cap. We also removed the entire door units with jams and casings. Problem is, the floors were originally installed after the doors and baseboard. So we now have a good 7/8 inch gap between the edge of the wood and the walls in every room and where the doors were pulled out with the jams there is a cut out shaped like the door jam/stops and old clamshell which was installed and then cut around. The hardwood looks as if it is laying directly on the joists. I am now trying to install new baseboard and if I buy new 3/4 preprimed 1×4 and a cap it still looks sloppy in some areas. I hate shoe molding as it looks like you are trying to cover up a join at least when it is rounded. Can I add any flat stock trim on the bottom as I only need to cover about 1/8 inch at baseboard area? Not sure what to do under door jam area. Is there any other creative way of replacing this all to look normal again? We need to put in new prehung doors as well so there is no molding on anything. The colonial casing fits the best back into the old cutouts were the clamshell was. If I buy baseboard that is 1 1/13 or 1/3/16 so I can sit it on top of the floor instead of trying to go back down,which I have seen, they tell me it wont but up well to casing which is only about 5/8 and that the casing should sit more forward than the baseboard. I’m wondering if hardwood installer could band the edges of every room!

Use plinth blocks at the casing to transition your trim profiles. Then you can use the thick base you mentioned and it won’t look funny. You could then do a more traditional built up style with whatever profiles you wanted.

Should i install the prehung interior doors before or after putting down the hardwood floors? And second where should I make the transition from hard wood to tile? At the door stop?

I would do the doors second, personally\ – but really either way is fine. You should make the transition half way under the door (where it closes). The idea is that you should see only hardwood from one room, and only tile from the other when the door is closed.

I am still not convinced I can do this one myself, but this is a helpful guide!

We will be installing 5 in pre-finished bamboo flooring. Does that material entail any modification in the guidelines which you’ve provided for other hardwood floors ?

Nope. Bamboo will work just fine using these instructions.

I need some advice. In a recent condo renovation, the contractor put engineered wood over the concrete floor (and a required cork sound abatement material). The problem is the concrete floor wasn’t perfectly level and the wood “pops” or buckles in certain places when anyone walks there. Do you know of any fix for this?

There is no fix. You have the get the subfloor level before installing the floor, unfortunately.

Going to install hardwood in the kitchen replacing ceramic tile. The reason is the floor gives a little bit when you walk on it and the grout will not stay in. Looks great for a year and then it start breaking up. tired of that. Is it imperative to install hardwood floors perpendicular to the joists. Or can it be installed parellel to them. What is the preferred method? Thanks .

Why is the staple not going all the way in when I nail(staple) the hardwwod floor. Have 100 to 110 pressure and really hit the nail gun but only one out of 4 staples is going in correctly. Staple gun is older but not ancient and compressor is new. any ideas what else it could be if I’m sure there is enough pressure?

Oil up the stapler, try using a slightly higher pressure. If you are installing an exotic hardwood, you need to make sure your stapler is rated to drive the wood.

I am installing 3/4″ by 5″ Hickory Harwood flooring in my Foyer, LR, DR, and Kitchen all of which are on the same level. I have a set of stairs that lead to my basement and am wondering if I start with there with a stair nose and start my flooring from that point squaring up the whole or should I start with the longest wall? or should I start from a center line the length of the all the rooms workin out from that center line? At any rate, how do I handle the stair nose going down if I do not start at that point?

Ralph, you may have to rip a board and then route a new tongue to be able to handle the stairs, but you don’t necessarily have to start at the stairs. Ripping and routing the board can be achieved with a table saw and dado blade kit.

Hey Fred, been reading a lot of your articles and have a question….I am laying floor in for rooms that run together. I was planning on starting on the kitchen wall against the cabinets and running into the other rooms. A wall exists in the middle of the four so in essence I will be doing two rooms, go though 2 door ways and then join the other two rooms as the floor meets up again. Make sense? Do I do the rooms separately or try running them all together?

Hi Fred.

We purchased a house witch had oak floors installed already. However, when it was installed, it was stapled into 3/4 OSB and especially in the kitchen there is a lot of unevenness, delamination and splitting. One contractor stated that the OSB does not have enough structure and gripping and that plywood should have been placed down before installing. We are thinking about replacing the carpet in our living room and stairs with wood but are also thinking that we should also replace the wood in the kitchen after first installing plywood. What would you recommend?

Thank you.

I would like to replace my carpet with wood flooring and was told I would have to rip up my particle board which is over plywood because it would shatter when the nails were driven into it. Is this true?

Should the existing baseboard molding be removed before installing a hardwood floor in a room?

[Reply]

Yes. Some people will choose not to but unless the baseboard is really tall, it won’t look good.

Fred,

Are you guys in Portland by chance? Just a guess based on your pictures.

At any rate, great guide. I just wish I had found it sooner. It would have saved me a ton of frustration.

I just installed 1600 sq ft. of some handscraped hickory. The floor looks nice, but it was a bear, especially since I didn’t do enough with the sub-floor first.

Anyhow, great resource, and I’ll be sure to check out the rest of your site as my “money pit” project keeps me busy. I like the fact you guys have discounts on the stuff I’ll need.

Regards,

Ivan

Nope, we’re here in Baltimore County, Maryland! Thanks for the nice comment.

should i install felt paper over the sub floor and then install the hardwood

Yes – red rosin paper. Read the “Laying the First Board” link in the article.

I recently had hardwood floors installed in my living room and dining room, one room flows into the other. there is no wall separating the rooms. it was supposed to be a continuous flow from one room to the next. it is not. the hardwood goes in one direction in the living room, it goes in a different direction in the dining room. the reason I was given for this was because of the way the floor joists go. there is a sub floor down in both rooms. I want the direction of the hardwood floor the same in both rooms.

is it possible to have both rooms in the same direction

Pat, you should be able to have the hardwoods going the same direction unless the subfloor was not sufficient for this configuration (doubtful). I can’t answer for certain given the lack of info on the subfloor and house, but my guess is the installer should have at least asked you what you wanted to do and apprised you of the risks (if any) before installing. On the other hand, I’m not sure you have much recourse with the installer, since technically they can argue that they did the job professionally, and the fact that you don’t like it isn’t really material for them.

Help! Our house has laminate flooring that was put down 14 years ago when the house was built. We have starting pulling up the old flooring and it was installed with no vapor barrier and was installed with u shaped 1 inch staples. There are staples every few inches and they aren’t coming up with the flooring! There are hundreds of them in every room and they stick up about one quarter inch above the plywood sub flooring. We are having about 1400 sf installed – my wife andI both work and it would take weeks to get them all up but we don’t wan to compromise our new floor. If we hammer them down – could we then have the SVC silicone vapor barrier and per finished 3/4″ click and lock oak flooring installed over the flattened staples? Thank you for any advice.

Dan Holloway Homeowner

Hammering them down is perfectly fine. You might end up hitting one every now and then and that could jam up your hardwood nailer, but mostly you’ll avoid them and they won’t be a problem. I don’t have a lot of experience with the silicone vapor barrier and click and lock product – you should ask the manufacturer that question.

These are good articles. I am going to install a Red Alder hardwood floor. These

boards have some knot holes in them, what would you recommend for filler in the knot holes. What is a good floor stain, and protective coating.

Thanks Charlie

Thank you for the excellent article on installing hardwood flooring. I’m considering doing this job myself but have a few questions I didn’t see in the earlier comments:

1. How do I figure out if I need to remove the trim before installing or just add quarter round afterwards rather than rip out the trim and reinstall?

2. I’m taking up laminate plank flooring in the kitchen and replacing it with the hardwood – do I need to take the toekick off the cabinets and get the laminate planks out completely or do I just install the hardwood up to the toekicks and add quarter round to match the cabinet?

3. How do I handle the hardwood around the kitchen oven? Do I take out the oven and install hardwood all the way back behind it?

Thank you for taking time to read the comments and questions as well as give thoughtful responses. Very much enjoying your blog.

Thanks,

mcblues

We just bought a house to use for rental property. The house has a sunken living room. We replaced the old wood laminant in the sunken living room with ceramic wood tile. We also used the same ceramic wood tile on the the surfaces on the rooms that but up to the sunken room. It looks like an optical allusion and I’m worried someone will fall and hurt themselves. What should we do to draw attention to the drop in flooring? Should our contractor have warned us about this?

Hi Fred,

We are finding a contractor to install Brazilian cherry hardwood floor,

some use staple gun,

some say exotic hardwood like Brazilian cherry needs to be nailed down with cleats, staple being too tight.

some use nail gun with glue because of 5” wide board.

What is your advise for us?

Thank you very much!

nan

I have a 1/2 inch sub floor. I have 1/4 inch particle board over the top of my sub floor. Can I nail my 3/4 inch hardwood without removing the particle board?

Question After I removed carpeting I found old 3/4 inch barn board flooring with several pieces of 3/4 inch plywood. Do I have to remove the old 3/4 inch wood before I put down the new 3/4 inch hardwood covering all the old wood?

Thanks for your help!

Hi Anne–Fred may weigh in and he is the expert, but I would say as long as all the old wood and newer plywood are the same level and is all solid and in good shape, and as long as the new flooring is perpendicular to the old barn board flooring, you should be in good shape to go right over it. Hope that helps!

Bill

Reading ur article was right up my alley. My flooring has several valleys and hills. I’ve been leveling and flattening out with 30# felt and 90# roofing rolls. Seems to be working well, but my question is should I still install allglobe silicone vapor shield over the existing felt and shingle underlayment after I’m done leveling. I have purchased the vapor barrier several years back. Also what is a easy way to measure and start my first row of 3/4 hardwood flooring? Looking forward to ur reply. Regards Joseph Obenhaus

[…] One Project Closer: How to Install Hardwood Flooring … – We first ran this article in 2010. It provides detailed instructions for installing hardwood flooring over a wood substructure. It chronicles tutorials for each step … […]

Our bamboo floor in Hawaii is being replaced because it cupped. The old floor was put over a vapor retarder, but in order to insure we don’t have cupping again, we purchased a new (and better we think) vapor retarder. Can we lay the new vapor retarder over the old and have two layers or do we have to remove the old stuff? The floor that is being removed is just over a year old. Thanks,

Kim Eyring

I will installing acnew hardwood floor in a existing construction with a couple of stairways. I will have 2 spots where the stair nosing will be perpendicular to the hardwood flooring. How do I handle the situation?

I have a 75 year old home that is on a conventional foundation that stays moist as I am in a humid climate in the south. I have to replace 4 rooms of red oak hardwood floors (including 3 rooms also need new subfloors). Can you tell me how the old floors would have been installed and if the new hardwood needs to be installed the same way? I have always heard these old floors need to breath over this type of foundation. What is the correct way to lay the hardwood? Thank you!

I have a 75 year old home that is on a conventional foundation that stays moist as I am in a humid climate in the south. I have to replace 4 rooms of red oak hardwood floors (including 3 rooms also need new subfloors). Can you tell me how the old floors would have been installed and if the new hardwood needs to be installed the same way? I have always heard these old floors need to breath over this type of foundation. Thank you!